In the realm of technology, the task of selecting a suitable Single Board Computer (SBC) for edge applications might initially seem straightforward. Yet, beneath the surface lies a labyrinth of considerations that can confound even the most seasoned decision-makers. Analogous to purchasing a new car, where factors like cost, brand reputation, and environmental suitability play pivotal roles, the process of choosing the right SBC demands meticulous attention. From understanding the unique demands of the application's environment to navigating budget constraints and identifying essential technical specifications, each step requires careful consideration.

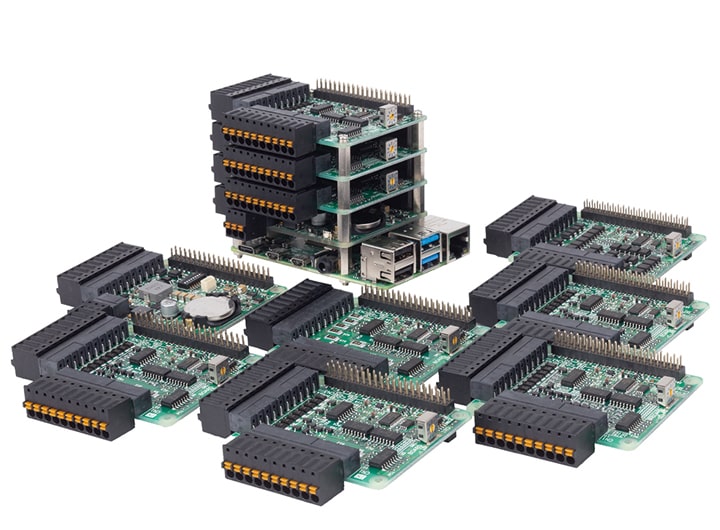

Our offering includes Raspberry Pi and Jetson Nano:

We developed new HAT size cards (7 models) for utilizing Raspberry Pi® computers in factory automation and measurement control applications. In addition, a RAS function expansion card adds industrial computer availability and maintainability to the Raspberry Pi.

These computers include 384 Volta cores for the GPU, and two NVDLA (NVIDIA Deep Learning Accelerators) for improved deep learning performance. In ResNet-50 inference execution comparisons, the DX-U1200 enables faster edge inference execution for high-performance AI applications, including about 5.5 times faster FP16 arithmetic precision and about 21.5 times faster INT8 arithmetic precision.

Manufacturing Control

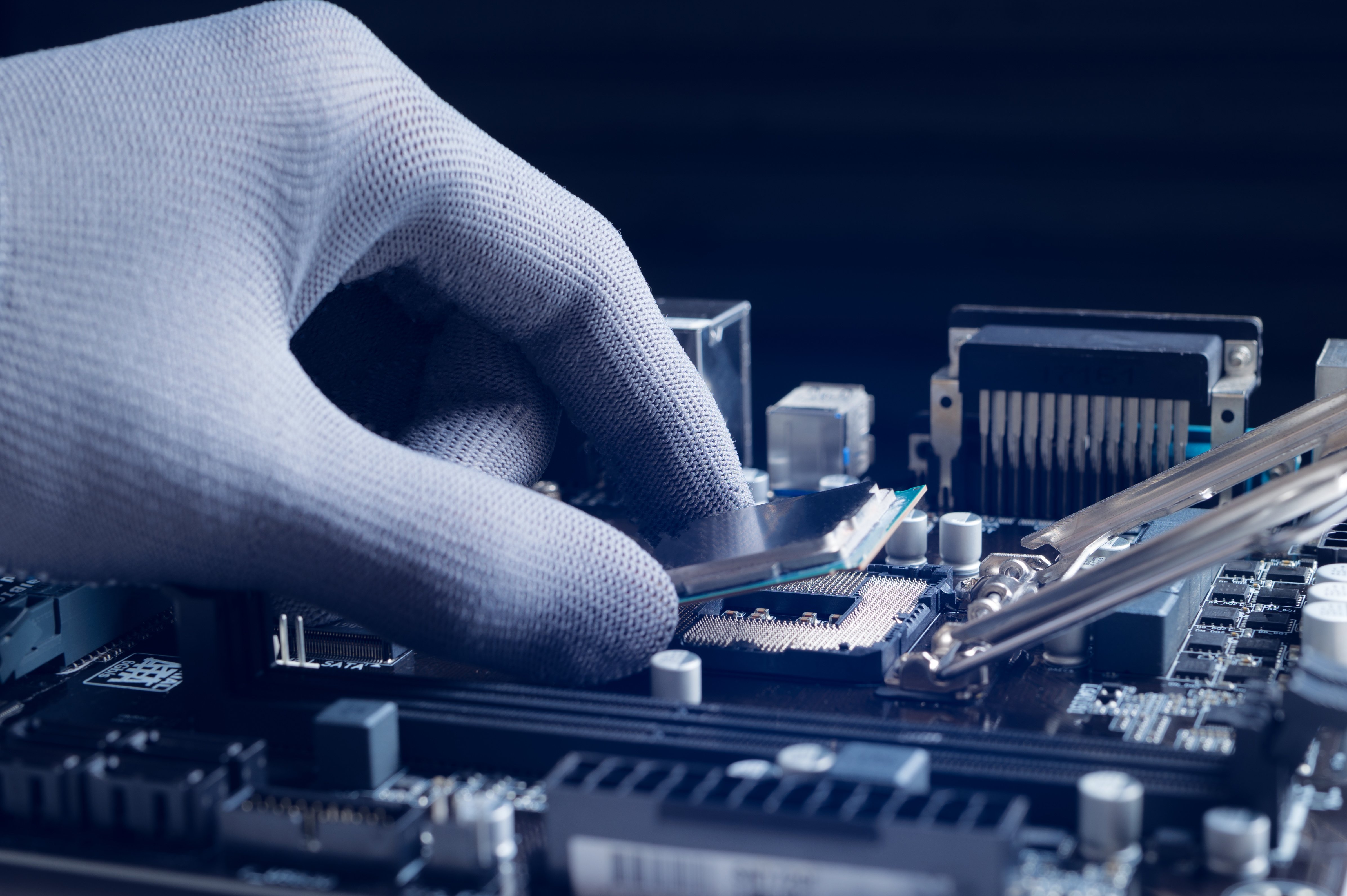

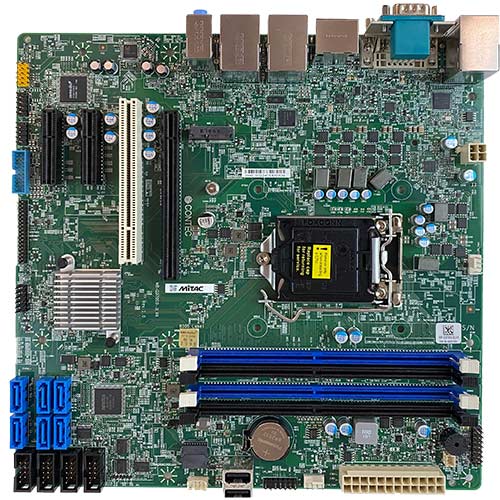

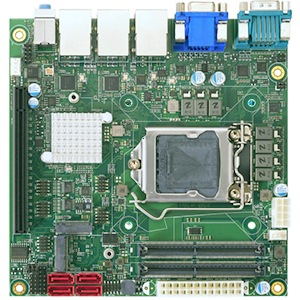

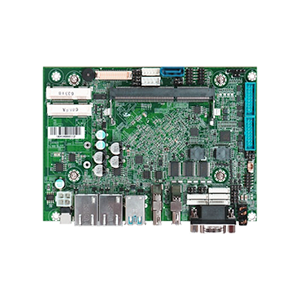

Contec motherboards and SBCs were designed by Contec to address the specific needs of our customers in a wide variety of industries around the world. Our boards are developed and manufactured in-house giving us complete control over the manufacturing life cycle.

Configuration Control

As the design owner, Contec owns the firmware down to the BIOS level for exclusive control over the configuration and product life cycle. The life cycle of a Contec board is typically 3 – 5 years and can be extended to as many as ten (10) and even fifteen (15) years and beyond.

Flexible Design and Manufacturing

Unlike larger board houses, Contec’s model is designed to be nimble and adaptable to specific needs.

Rugged, Industrial-Grade Motherboards and SBCs

As a leading industrial electronics manufacturer since 1975, Contec understands the importance of product quality and reliability in industrial environments. Our motherboards and SBCs feature isolated circuitry and are tested to meet rigorous industry standards.

Global Engineering Support and Manufacturing Capabilities

Our expertise isn’t limited to a single Contec facility. With over 240 R&D, engineering, and technical support resources worldwide, Contec motherboard and SBC experts and manufacturing capabilities are accessible to you from our U.S., Taiwan, and Japan locations. As a result, Contec is able to offer competitive lead time and support services to customers around the world.

Standard Motherboard and SBC Offering: Reliable, Long-Life Motherboards and SBCs for Industrial Applications.

Semi-Custom Board Design: Customer-Specific Design Modifications to Current Reference Designs.

Fully Custom Board Design: Complete motherboard and SBC custom design from the ground up.

Expert Engineering Guidance and Support: Globally available experts for needs analysis, design consultation, and support requirements.

Global Manufacturing and Prototyping: Motherboard and SBC prototyping and manufacturing capabilities in the United States, Taiwan and Japan.

Our product offering adapts to your needs:

Our boards were designed for industrial applications:

From cutting-edge electronic components and subassemblies to complete end-product design and manufacturing, Contec has the right mix of innovative products, custom engineering capabilities, and global manufacturing and support to meet all of your industrial technology needs.

Our compact embedded PCs can reduce equipment size, lower costs, and improve functionality. We understand that for our industrial customers, reliability is the single most important factor when choosing their technology.

Our Industrial Communications offering includes compatibility with several OEM’s and communication protocols. Our rugged industrial hardware is easy to install and requires little to no programming or training.